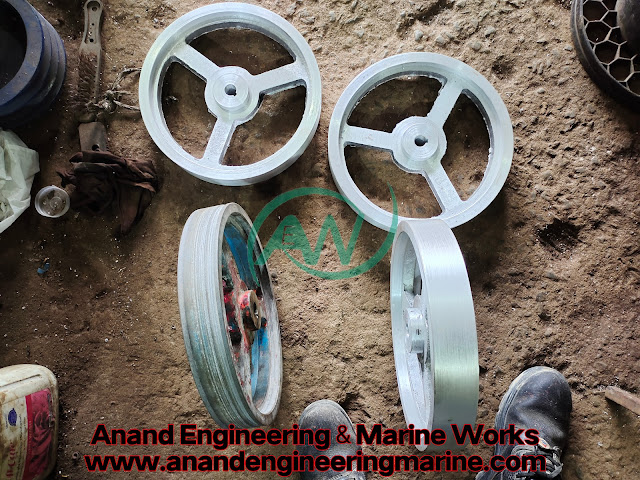

Sure, I'd be happy to explain the process of manufacturing a flat belt pulley from aluminum based on a sample at Anand Engineering & Marine Works company.

Material Selection: The first step involves choosing the appropriate grade of aluminum based on the specific requirements of the pulley, such as its size, load-bearing capacity, and intended use.

Pattern Making: A pattern is created based on the sample pulley. This pattern serves as a template for creating the mold that will be used to shape the aluminum into the desired pulley form.

Mold Preparation: The pattern is used to create a mold cavity. This mold can be made of sand or other materials suitable for casting. The mold is created in two halves to allow for easy removal of the finished pulley.

Melting and Pouring: Aluminum is melted in a furnace to its liquid state. Once the desired temperature is reached, the molten aluminum is poured into the prepared mold cavity.

Cooling and Solidification: The molten aluminum cools and solidifies within the mold, taking on the shape of the pulley cavity.

Mold Removal: Once the aluminum has completely solidified, the mold is opened, and the rough casting of the pulley is removed. This casting will have excess material and rough edges.

Trimming and Finishing: The rough edges and excess material are trimmed off from the casting using various machining techniques such as cutting, grinding, or milling. This step brings the pulley closer to its final shape.

Machining: The pulley undergoes precision machining processes like turning and milling to achieve the exact dimensions and surface finish required. This step ensures that the pulley is well-balanced and functions properly.

Surface Treatment: Depending on the specific requirements, the pulley might undergo surface treatments like polishing, anodizing, or coating to enhance its appearance, durability, and resistance to corrosion.

Quality Control: The finished pulley undergoes thorough quality checks to ensure that it meets the required specifications and standards. This can involve measurements, inspections, and functional tests.

Packaging and Delivery: Once the pulley passes quality control, it is properly packaged to prevent damage during transportation. It is then ready to be delivered to the customer.

Throughout the process, precision, attention to detail, and adherence to quality standards are crucial to ensure that the final product meets the required specifications and functions effectively as a flat belt pulley

Comments

Post a Comment